A cable de control apantallado úsase xeralmente como liña de conexión de instrumentos eléctricos.

É adecuado para a liña de conexión de instrumentos eléctricos cunha tensión nominal de CA de 450/750 V e inferior e a liña de transmisión do sistema de control automático..

Ten excelentes propiedades como a resistencia ao aceite, resistencia á auga, resistencia ao desgaste, resistencia a ácidos e álcalis, resistencia a diversos gases corrosivos, resistencia ao envellecemento, e incombustible.

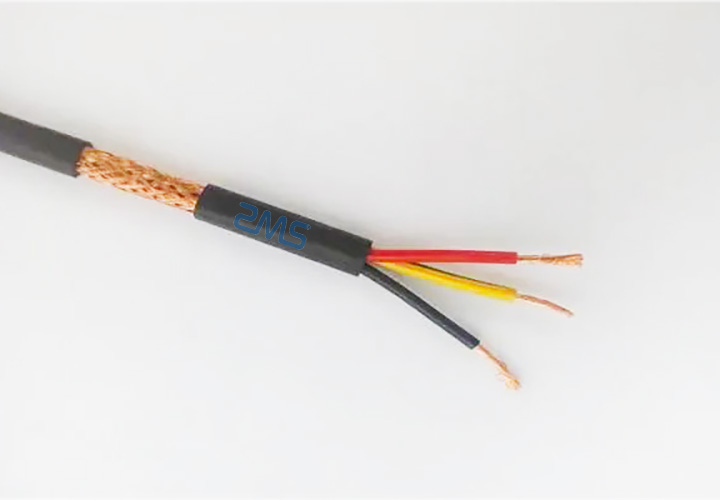

A cable de control apantallado is a cable with a layer of mesh copper or metal wire woven around one or more wires. This layer of mesh metal wire can prevent lightning strikes and external signals cannot interfere with it.

The shield also provides some leakage protection. If the cable is damaged during use and leaks, the shield can direct the leakage current to the ground wire, providing some safety protection.

The role of shielding and grounding wire of shielded control cable is that the shielding layer is divided into internal shielding and external shielding.

They are both to make good contact between the cable conductor and insulation layer, and between the cable insulation layer and the inner protective layer, to eliminate the increase of surface electric field strength caused by the unsmooth surface of the conductor and the inner protective layer.

Product characteristics of shielded control cables.

(1) Allowable bending radius of the cable: the minimum bending radius of a non-armored cable is 6 times the outer diameter of the cable. Fluoroplastic insulated and sheathed cables should be at least 8 veces o diámetro exterior do cable. Copper tape shielded or steel tape armored cable should be at least 12 veces o diámetro exterior do cable.

(2) Maximum operating temperature: polytetrafluoroethylene propylene (F46) insulation should not exceed 200 ℃. Soluble polytetrafluoroethylene (PFA) insulation should not exceed 260 ℃.

(3) Minimum ambient temperature. PVC sheath: fixed laying -40℃, non-fixed laying -15℃. Fluorine plastic and silicone rubber sheath: fixed laying -60℃, non-fixed laying -20℃. Cable installation and laying temperature shall not be lower than 0℃ (fluoroplastic, silicone rubber and nitrile sheathed cable shall not be lower than -25℃).