Braided cables are required for stability.

Crossed threads allow the braid to flex and stretch without bending, folding or kinking.

There are excellent electrical conductors braided cables and an electrostatic shield to ensure signal integrity.

Copper, tinned copper, and aluminum are examples of these conductors.

Braided wires can be made from a variety of materials if designed for mechanical strength or toughness such as steel wire, nylon thread, and fiberglass.

Braided wire cables provide additional protection against hot surfaces by resisting abrasion and cutting.

Braided cable wires also deter rodents.

Wire harnesses can be made by weaving wires together.

What is A Braided Cable?

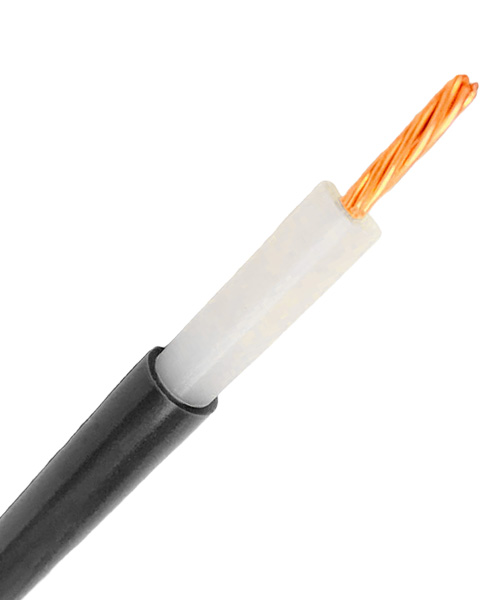

Braided cables are formed using braided mesh or braiding over stranded conductors.

This is typically achieved by braiding together multiple strands of plain or tinned copper wire to achieve the desired braid coverage.

Braided cables typically provide 80% coverage.

But if you have specific needs, we can also adjust specifications.

We have braided cable 3 cores for metal lighting fittings and it is a flexible braided cable.

We also have a flat braided copper cable attached to the tube and squashed by 0.20 diameter wire.

Smaller diameter wires are used for lower current ratings, increasing flexibility.

Flexible wires are designed to withstand physical stress and tight flexing in mobile applications. Flexible braided cables are flexible, lightweight and fire resistant.

Our cables are braided by professionals.

Are Braided Cables Better?

Braided cables are primarily preferred due to the following properties.

Durability: High tenacity fibers give them long spans.

High elongation properties: Braided materials such as nylon have strong tensile properties, which makes it easy to braid.

Abrasion Resistance: Braided cable wires are extremely durable. It has excellent wear resistance. They are suitable for any condition.

Resilience: Braided cable is elastic and has no difficulty with heat.

High Resistance: Braided cables are also resistant to mold, mildew, rot, and many chemicals are resistant to insects, fungi, and animals, as well as mold, mildew, and rot.

It’s important to use materials that will melt rather than burn, such as nylon, as your equipment cables are less likely to burn in a fire.

Since your cables are less likely to burn in a fire, it’s better to use materials that can melt rather than burn.

Are Braided Cables More Durable?

Braided ground cables will have a long lifespan if fixed properly.

Braided wire is generally flexible and has less tear and damage.

Braided cables are also a great value and will serve you well even in heavy use.

They’re also waterproof – however, it’s best to keep them safe and avoid contact with water.

What is A Shielded Cable?

Cables with insulated conductors are called shielded cables or shielded cables.

Braided wire of copper (or other metals such as aluminum), helices of copper tape wrapped in a non-braided helix, or layers of conductive polymers can all be used to make the shield.

The shielding layer acts as an enclosure, preventing electrical noise from interfering with signals and electromagnetic waves from interfering with other equipment.

The barrier reduces capacitively coupled noise from other power supplies.

In order to function properly, the shield must be grounded.

The shield is used as a return path for the signal or only as a shield in a shielded transmission line

What Is the Difference Between Armored Cable and Braided Cable?

Armoured cable is a standard cable with an extra layer of protection that prevents it from being cut or damaged.

Due to the armoring, the performance, reliability and safety of the cable core are improved. Armour protects the wire from lethal injury if it is open circuited and unprotected or running underground.

It is often required for marine, offshore and hazardous environment applications.

Braided copper armor is the easiest for installers to use because the cable is (to some extent) easier to pull.

Copper braids can be used as safety ground conductors in certain applications.

The most complex type of armor weave is the single wire armor weave.

In most cases, cables are usually stiff and have a large bend radius.

However, it provides the most satisfactory mechanical protection for the cable.

Steel braided cables suppress magnetic fields and reduce electromagnetic interference between it and nearby cables.

Armored cables require a unique Class 2 gland to ensure air and water tightness when the cable is introduced into panels or equipment.

You need a lot of talent to get things done right.

How Are Braided Cables Made?

Due to the different scale and overall performance of the wire and cable industry, large-scale investment and the revival of equipment companies.

Existing equipment inventions and object modifications are not currently or in the future possible.

Therefore, the transformation of equipment and technology has a great market in reducing product cost and improving quality.

The following sections discuss shielded cable production up to 7 conductors and other braided shielding procedures and equipment enhancement strategies.

Defects in Initial Production Methods and Processes

In the past, several companies have commonly used cage stranded equipment in cable and stranded wire production.

Their machines have low productivity, high costs and long lead times, making it difficult to meet customer expectations.

The result is a negative impression of the corporate image.

The above products are all transformed through the pipe stranding machine, and the production efficiency is high.

The tube stranding machine itself also has its weaknesses.

First, the tube stranding machine has no filling device in the cable.

Second, some existing pipe stranding machines do not have a winding structure.

So using cables and wrapping them not only increases productivity but reduces efficiency.

It also improves the product quality of the production line.

Therefore, some companies have considered improving their equipment and procedures.

Make up for the deficiencies in the production process of the pipe stranding machine, the necessary actions are as follows.

Process and Production Process Improvement

Due to the challenges brought by the existing equipment, the company’s production department actively advocated the implementation of the original production process improvement plan.

The reason is to meet energy and labor cost management goals.

First, the pipe stranding machine is filled and rewound to 500 turns before being loaded into the cable, and twisted together with the core wire.

After the cable is formed, the braiding machine adds polyester tape longitudinally.

The cable cores are put together through the die of the braiding machine, and after longitudinal winding in the die, the completion is completed and brazed with copper wire.

After the cable is formed, the braiding machine adds polyester tape longitudinally.

This includes connecting the cable cores together through a braided mouth die,

Problems and Treatment after Improvement

However, when the core is woven, the two longitudinal edges of the polyester tape pass through the die.

When irregular deformation occurs, the longitudinal winding of the polyester tape is completed, overlapping the two longitudinal directions together with irregular raised edges.

It causes fringing.

When the polyester tapes are lapped together, the two longitudinal edges are not well connected. The result is leakage and severe wrinkling after longitudinal winding.

It also leads to uniform outer diameter of the cable core after longitudinal winding, and poor braiding uniformity.

In response to the complaint phenomenon, the company’s technical department conducted an analysis and research.

Some suggestions

On the basis of the original knitting machine mold design, the mold structure and principle are improved and improved.

Therefore, the knitting machine die has a longitudinal corner area.

It has stabilizing regions of the two-region structure through which the polyester tape is deformed.

The deformation process is as follows:

Polyester tape is continuously wound on the cable core after braiding of copper wire.

It undergoes an initial deformation from a flattened to a similar tubular structure through the longitudinal pocket area.

Further deformation is then carried out through the stabilization zone to bring the diameter of the tubular structure close to the design value.